Home » Search results for 'George Longden'

Search Results for: George Longden

Woodbine Cottage, 14, & 16 Bollington Road

|

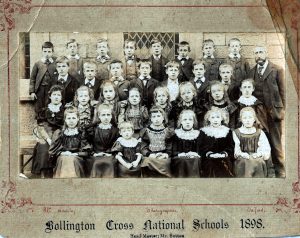

Situated directly across the road from Bollington Cross School were numbers 14 and 16 Bollington Road. Number 14 was called Woodbine Cottage on the 1911 census, and was also known as the Schoolhouse probably because Headmaster of Bollington Cross school Herbert Sutton and his family lived there for many years.

Originally Kingsway the road on the left in the photographs above, was absent as it wasn′t built until around 1930. So the garden to number 14 was large, covering Kingsway entrance and coming right up to the road edge at the front with mature surrounding hedge and trees. Photos of the Sutton family in that garden can be seen on the Bollington Photo Archive website![]() .

.

Census

For number 14 which is the left side of the house as seen from Bollington Road:

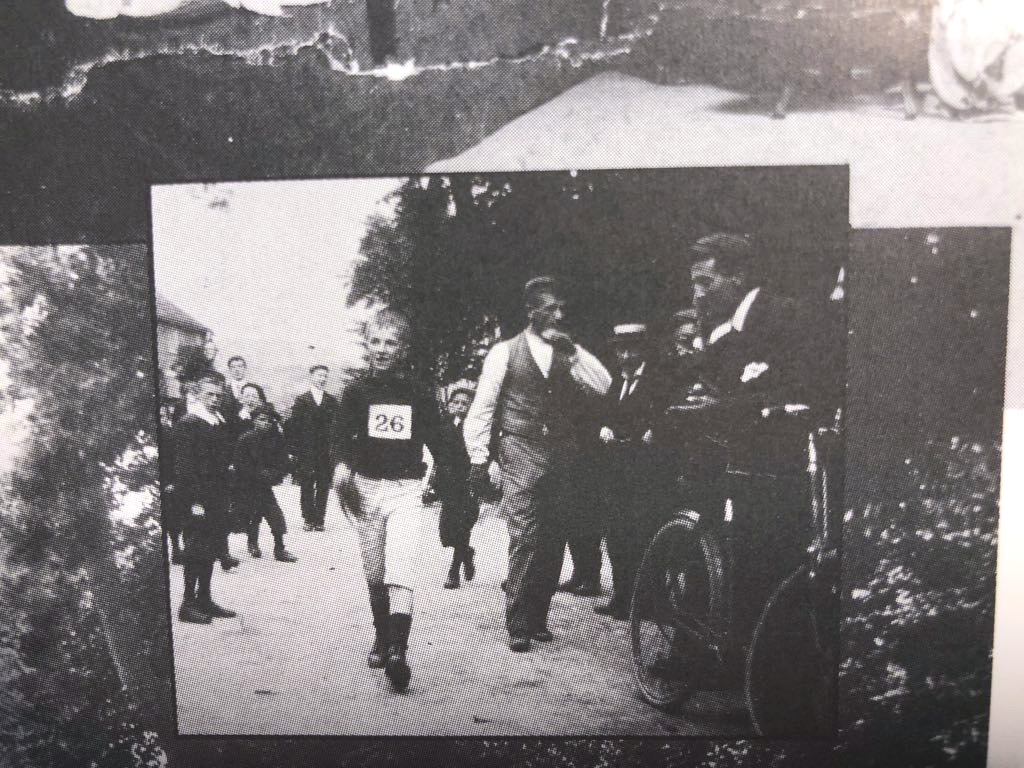

1881: Herbert John Sutton aged twenty five years lived at number 14. Occupation Schoolmaster from Bollington from 1877. He was the secretary of the Horticultural Society from 1885. He also organised the Annual Sports and Flower Show and was Choir Master of St Oswald′s Church at Bollington Cross. Also living with him was his wife Hannah of the same age and from Wiltshire. They had two children at this point, Maud two years and Joseph H. aged one year. Also living with them was Mary Hayward, Hannah’s mother aged fifty five years and from Gloucester.

1891: Ten years later Herbert and Hannah Sutton had four more children, James eight years, Edith C. seven years, Mary L. five years and baby Herbert J. aged just five months. Mother in Law of Herbert senior Mary Hayward was still living with them.

1901: Nothing has changed ten years later apart from their ages of course. Herbert resigned from being headmaster in this year due to illness and died in 1909 aged fifty four years

1911: Joseph Hayward Sutton first born son of Herbert John Sutton is now resident of number 14 with his family. Joseph’s father Herbert John senior died in 1909 whilst still at number 14 (Woodbine Cottage). There is no record on Herbert’s wife Hannah, Joseph’s mother. Joseph is now thirty one years of age and his occupation is Clerk to Master in the Royal Exchange. His wife Elizabeth Blower was twenty eight years old and from Denbighshire and previously living in Ledley Street, Bollington. They had a one year old child at this point named Mary. Elizabeth’s mother Sarah Blower, a widow aged fifty nine years, also lived at number 14 at this time, as did Joseph’s brother Herbert John junior aged twenty years. Herbert was a Mechanical Engineer.

1939: Joseph H Sutton was still living at 14 Bollington Road with his wife Elizabeth with daughters Mary aged twenty eight years who was an insurance clerk, Maud twenty five years, and Bessie twenty years and was a school teacher. Also living at number 14 and about to go and fight in the second world was Joseph’s son Richard aged twenty three years. Richard was a representative in textiles at this time. He married Rowena Mary Bamford in 1941 and lived at 118 Palmerston Street. Richard sadly died on 18th April 1943 when his submarine HMS Regent![]() was lost with all hands while in action in WWII after, it is believed, hitting a mine off the coast of Barletta, Italy. Bollington’s war dead

was lost with all hands while in action in WWII after, it is believed, hitting a mine off the coast of Barletta, Italy. Bollington’s war dead![]() .

.

Maud, Joseph’s daughter, was the last Sutton living at Woodbine until her death in the 1990s.

Census

For number 16 Bollington Road:

1911: Mary Ellen Sutton a sixty six year old retired school mistress and sister of Herbert John Senior lived at number 16 with servant Marion Turner aged twenty three from Bollington. Mary had spent all her life in Church Street Bollington. She finally moved next door to her brother Herbert some time around 1900, sadly he passed away in 1909.

1926: John Harding lived at number 16.

1939: John Harding aged fifty five years was still living at number 16. He was a Chief Clerk at a cotton mill. He lived with his wife Roberta aged fifty years and their family.

In the mid 1900s number 16 was occupied by the Green family, Alf (Alfred) and Nellie (Ellen) and their children Brenda, John, Maurice, Margaret and Janet.

Later number 16 was occupied by the Dankins family, John, Amy and children Pauline and John. The Dankins were still there in 1996.

|

|

Your Historic Documents

Please don't chuck out those historic documents and pictures! Find out why here.

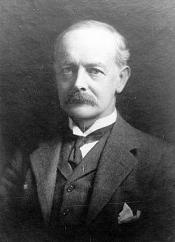

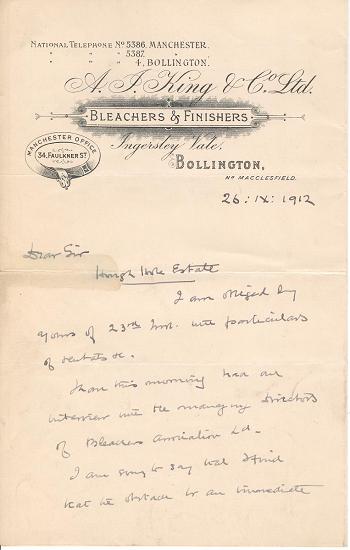

Alfred J King

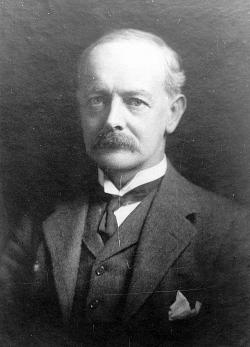

Industrialist, Councillor and Member of Parliament

The following extracts are from George Longden’s report to the KRIV project[1] ….

Ingersley Vale Mill … by 1878 (27)[2] the long occupation of the mill by the bleaching and finishing firm dominated by members of the King family had begun. The firm appears as Bates & King in 1878 (27)[2] and 1883 (33)[3]; William King & Co in 1887-8 (25)[4]; and A.J. King & Co from 1892 (44)[5]. The firm became part of the Bleachers’ Combine around 1900, but retained its name and management.

Alfred J. King was living at Clough Cottage (formerly Clough House, I presume) by 1890 (45)[6], and may have been effectively in charge by then. Allan Bates lived at the Rookery. Alfred King was the dominant partner and Bates later dropped out. Under A.J. King the firm seems to have been a progressive and expanding enterprise. Various developments had a physical impact on the Ingersley Vale site. The first were the extensions of 1895. The local paper announced that these were to consist of a one storey shed, 82 feet square, to “accommodate a number of calendars used in the process of bleaching”, and a two storey warehouse, 40 feet by 25 feet. These were to be situated south of the mill, built across and to the east of the river – the northern end of the block of buildings which can be seen today [2005, since demolished]. The shed occupied the former lawn of Clough House. The house was demolished, and A.J. King moved to Rock Bank House. It was decided to drive the new machines by electricity, and use electricity to light the whole works (20, 23 Mar 1895, 22 Jun 1895, 5 Oct 1895)[7]. …

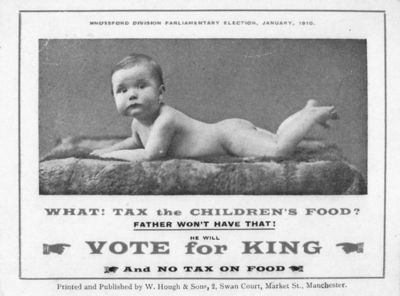

A.J. King lived at Limefield (1898) and became a progressive Liberal member of the Bollington Urban District Council, and played an important role in the completion of the waterworks scheme and in instigating a drainage scheme with a sewage works for the village. He represented Bollington on the Cheshire County Council from 1901 to 1906, and from 1906 to 1910 was Liberal MP for the Knutsford Division [which then included Bollington. See election poster left]. After electoral defeat in 1910 (he was beaten by Col. Sir Alan J. Sykes

A.J. King lived at Limefield (1898) and became a progressive Liberal member of the Bollington Urban District Council, and played an important role in the completion of the waterworks scheme and in instigating a drainage scheme with a sewage works for the village. He represented Bollington on the Cheshire County Council from 1901 to 1906, and from 1906 to 1910 was Liberal MP for the Knutsford Division [which then included Bollington. See election poster left]. After electoral defeat in 1910 (he was beaten by Col. Sir Alan J. Sykes![]() a big noise in the bleaching industry who in 1928 opened the Bowling Green in Ingersley Vale), Alfred King and his family moved to Windermere, where they were visited from time to time by parties of workers from Ingersley Vale (48, p33)[8].

a big noise in the bleaching industry who in 1928 opened the Bowling Green in Ingersley Vale), Alfred King and his family moved to Windermere, where they were visited from time to time by parties of workers from Ingersley Vale (48, p33)[8].

See Ingersley Vale mill for an A. J. King & Co Ltd document.

References

Clicking the reference description takes you back to the text.

- Kerridge Ridge & Ingersley Vale, An Historical Study, George Longden, 2002.

The study document (PDF)

- Greenwood’s Cheshire Map, 1819

- A M Tonkinson, Macclesfield In The Later Fourteenth Century, 1999

- Agreement between George Antrobus and Joseph Wagstaff, fragments, nd, Bollington Civic Society archive, Antrobus collection, no.9. George Antrobus

- Not identified

- Not identified

- Jane Laughton, The Place Names Of Rainow, articles in Contact, the Parish Magazine of Rainow with Saltersford and Forest, January 2000 – May 2001

- Not identified

Your Historic Documents

Please don't chuck out those historic documents and pictures! Find out why here.

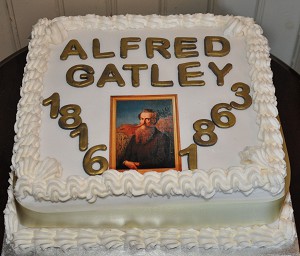

Alfred Gatley

Sculptor, 1816-1863

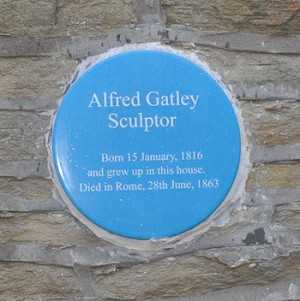

The 200th anniversary of the birth of Alfred Gatley was celebrated on Friday 15th January 2016. A ceremony was held at his birthplace at Spring House in Kerridge, when a Blue Plaque was unveiled to his memory.

|

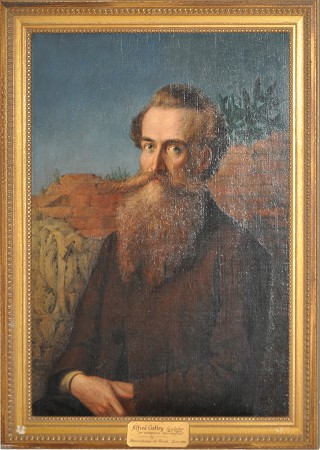

Alfred Gatley was born at Spring Cottage (today known as Spring House), Kerridge, on 15th January 1816. His father owned and worked two stone quarries in Kerridge Hill. Alfred showed very early promise as a sculptor and took this up professionally. He spent much of his career in Rome, Italy, carving in marble. He died on 28th June 1863 at age 47, in Rome, where he is buried. There are many examples of his works in Bollington and the Cheshire and Manchester/Salford area as well as more widely. While the whereabouts of many of those pieces in private ownership were known in the 1960s I suspect that the passage of time will have resulted in some of them being widely distributed and beyond normal search. The late Dr John Coope used examples of Gatley’s work in the displays for the very first of his Bollington Festivals, in September 1964, and in preparation he and Harry Cole did a lot of research into Gatley with a view to writing a biography. Unfortunately the book never materialised but all Dr John’s papers and pictures were most generously donated by his widow, the late Dr Jean Coope, to Bollington Civic Society and they provide the basis of this page. The 200th anniversary of Alfred Gatley’s birth was celebrated by the unveiling of a Blue Plaque on his birth place, Spring House in Kerridge. WorksThis is a very incomplete list of Alfred Gatley’s works, the first part compiled by Dr John Coope and Harry Cole for the 1964 Bollington Festival. The details given are the subject, date of execution, last known location.

The following list is taken from a list of exhibitors at the Royal Academy in 1854. The whereabouts of all except one of these is unknown.

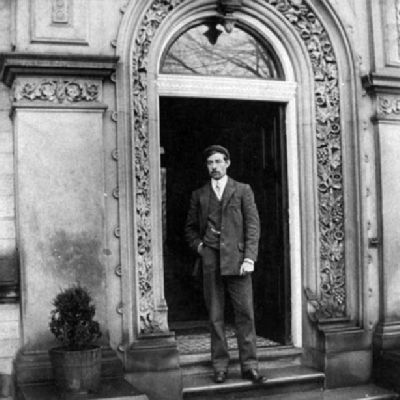

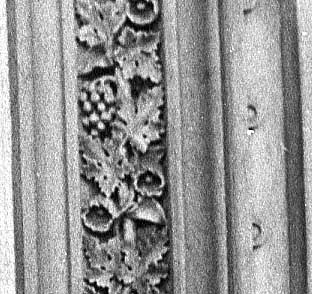

* The Hon. Augustus H Vernon was a member of the Poynton Vernon coal mining family. Other works by Gatley are, or were in recent years, at Lyme Hall; Salford City Art Gallery; St Mary’s Church, Disley; Mottram in Longdendale church. The two bas relief panels known as the Craigentinny Marbles (above right) were described at the time of installation in 1867 as “The most remarkable pieces of sculpture executed during this century.” The original Oak Bank House in Bollington, erected in 1858, had a very fine carved front door surround and frieze (picture right). Dr John Coope believed that this may have been the work of Gatley. Sadly this fine piece was lost when the house was demolished in the 1940s. Alfred Gatley’s 200th birthday was celebrated by the unveiling of a blue plaque (see above right) and the guests were refreshed at the Bull’s Head with coffee and a delicious cream and sponge cake baked and supremely decorated by Paul from Belfield’s Bakery in Palmerston Street.

|

Alfred Gatley, 1816-1863, Sculptor Alfred Gatley, 1816-1863, Sculptor by Marcianno da Tuna, Rome 1862 Shown by the very kind permission of the late Mr Timothy & Mrs Elizabeth Richards of Gawsworth Hall where the painting and other Gatley artefacts can be seen during house tours.  Blue plaque unveiled at his birthplace Blue plaque unveiled at his birthplaceon the 200th anniversary of his birth.  Echo – popular girl! Echo – popular girl!Gatley is known to have carved three of these! This one is on view at Gawsworth Hall.   Two bas relief panels known as the Craigentinny Marbles Two bas relief panels known as the Craigentinny Marbles

George Swindells and his wife Elizabeth Swindells

Oak Bank House front door surround (this is not Alfred Gatley standing there!). What a pity that the photograph didn’t include the whole of the door casing. Detail from the picture above.

|

Extract from KRIV report by George Longden1William Broster asserts that Alfred Gatley was born in “the family home”, Gatley’s Yard – though it has to be said that Broster is not very reliable on historical matters outside his own experience [27]. According to the Dictionary of National Biography (DNB) [47], “while still a child [Gatley] learned the use of a stonemason’s tools from his father, who owned and worked two quarries in the Kerridge hills.” Alfred was educated at Rainow School where, tradition says, he carved his first work, his teacher’s head, out of a turnip [35, p.74]. Here, his ability, both artistic and general, was observed by the Rev. J. Sumner, the vicar of Pott Shrigley, who seems to have given him some private tuition alongside his own children [51]. After school he assisted in the family quarry, and here what Broster says was his first sculpture in stone, a figure of Walter Scott’s Tam O’Shanter, was completed. This work came into the possession of the Rev. Sumner, who loaned it in 1839 to an exhibition organised by the Macclesfield Useful Knowledge Society in Macclesfield Town Hall [16, 29 June 1839]. Two years earlier, in 1837, Gatley had moved to London, “aided by a few friends” as the DNB puts it. He worked in the studio of Edward Hodges Baily RA FRS, until in 1843 he became assistant to Musgrave L. Watson. In his early years in London Gatley studied in the British Museum, and then became a student of the Royal Academy, exhibiting there for the first time in 1841. Among works Gatley sold in his London period were figures of Cupid and Psyche, for Martin Swindells of Bollington, the memorial for the jubilee in 1846 of the Macclesfield Sunday School in Roe Street, and a bust of Dr. Sumner, archbishop of Canterbury and brother of the vicar of Pott Shrigley. The bust of Sumner was exhibited at the Royal Academy in 1848, and at the same time a cast of it was on display in Macclesfield Town Hall. The Macclesfield Courier commented that “the success of this rising young artist has been almost without parallel” [16, 15 July 1848]. In spite of a growing reputation, Gatley remained in tight financial circumstances. In 1852 he moved to Rome, where he took a studio on the Pincian Hill. Here, he still struggled to find adequate patronage, as his letters home show. In 1860 the Rev Sumner wrote to Gatley, mentioning an old acquaintance with artistic ambitions; Gatley replied “I certainly pity him if he does not pocket 10 times per annum more than I do” [48]. Gatley’s letters, incidentally, also suggest complex (and contested) Gatley family properties and finances in Kerridge. Gatley exhibited his bas-relief of ‘Pharaoh and his Hosts’ at the International Exhibition in London in 1862. This was to be the occasion of Gatley’s last visit to England; he died from dysentery in Rome on 28 June 1863, and is buried in the English cemetery there (picture above right). The rumour that he was poisoned by jealous Italian sculptors was prevalent in Kerridge for many years. An obituary for Gatley appeared in the Art Journal: “He had a mind of singular independence. The style he chose admitted of no facile compromise of the classic with the pictorial. It descended not to seek an easily purchased popularity by softly blended forms after the manner of the Romantics. The school to which he belonged was stern and strict. The English public failed to comprehend the largeness of his manner” [57]. Alfred Gatley’s diary and letter books and desk, a portrait of Gatley painted in Rome in 1862, a bust of Milton in Kerridge stone (1833), a reclining figure of a young girl, ‘Echo’ (1850), and a bas-relief panel ‘The Triumph of Britannia’, all by Gatley, are listed in Raymond Richards’ Manor of Gawsworth (1974 edition) as being in the Gawsworth Hall collection [49]. ‘Echo’ is illustrated in Richards’ book, as it is in the brochure for the first Bollington Festival in 1964, which also contains a photograph of Gatley, impressively wild in hair, beard and eye [50]. Other works by Gatley are (or were recently) at Lyme Hall; Salford City Art Gallery; St Mary’s Church, Disley; Mottram in Longdendale Church; and Bollington Medical Centre [58]. William Broster, it seems to me, made a good point when he wrote that “it is unfortunate and regrettable that nothing in [Gatley’s] native village remains to perpetuate his memory and outstanding eminence as a sculptor of national fame in the Victorian era” [27]. We have put right the last regret above on the 200th anniversary of Gatley’s birth, 15 January 2016 – see top of page. [Webmaster] |

References in this section marked [nn] … 16. MACCLESFIELD COURIER, microfilm, Macclesfield Public Library 27. William S. Broster, BOLLINGTON & KERRIDGE 1830-1980, 1980 35. W. Norton Betts, BOLLINGTON THROUGH THE CENTURIES, 1934 47. DICTIONARY OF NATIONAL BIOGRAPHY, 1993 ed., vol 7 48. ALFRED GATLEY’S DIARY AND LETTERBOOKS, from a transcript formerly in the possession of Mrs Rathbone, Bollington Cross 49. Raymond Richards, MANOR OF GAWSWORTH, 1974 edition 50. ALFRED GATLEY, KERRIDGE BOY WHO BECAME A SCULPTER (sic), Bollington Festival Brochure, 1964 51. John Earles, HISTORY OF OLD MACCLESFIELD, one of series of articles in the Macclesfield Courier, 31 March 1917 57. Rupert Gunnis, DICTIONARY OF BRITISH SCULPTORS 1660-1851, revised ed (nd) 58. NOTES ON THE WORKS OF ALFRED GATLEY, handwritten ms in hands of Dr John Coope (now in Bollington Civic Society collection)  It reads – Believe me to remain Unfortunately there is no date, indeed, the body of the letter appears to have been cut off and discarded. While the Victorians tended to use over flowery text in their writings, it is possible that Mr & Mrs Clayton (probably of Kerridge) were patrons of Gatley and financially supporting him while he was failing to earn enough to live on, which was the case for most of his career. |

Links

- https://www.geo.ed.ac.uk/scotgaz/features/featurefirst8582.html

- https://www.edinburgharchitecture.co.uk/craigentinny_marbles.htm

- Gawsworth Hall – Tudor Manor House with covered garden theatre

Reference:

Clicking the reference description takes you back to the text

Acknowledgements

Thanks to those whose research made these pages possible

We wish to offer the fullest acknowledgement to the Bollington Civic Society Historical Group who spent many years in the 1970s, 80s and 90s researching the history of Bollington, its people, its mills and other industries. The principle historians were George Longden, Molly Spink (who is still active) and Roger Bowling. They were supported by James Hough, Christabel Burgess, G R Alexander, Geoff Coe, Brenda King, David King, A Fearnhead and others. Further later work was carried out by George Longden for the Kerridge Ridge & Ingersley Vale project. We, the people of Bollington, owe them a great debt of thanks for collecting and preserving our historical heritage!

One of their greatest achievements was the collection of more than 5,000 historically important pictures which were so generously donated by the people of Bollington – indeed they are still passing to us most interesting and valuable pictures and documents today (if you have something of interest please see this page). The late Dr John Coope was instrumental in both setting up the Historical Group (as part of his already established Civic Society) and in encouraging the residents of the town, most of whom were his patients, to search out and make available their pictures. These pictures have been digitised and are available for all to search, view and enjoy at the Discovery Centre (a Bollington Civic Society project) and online here![]() .

.

A selection of the history gleaned by this group, together with some of the pictures, were published in various books. Most are now out of print but one, Looking Back at Bollington, has been reprinted and is available at the Discovery Centre or by mail order. The high cost of republishing these books has prevented the Civic Society from making more available. However, the internet and the Happy Valley web site provide an affordable means of making the material available to a wider public.

I also acknowledge the work of the Wilmslow Historical Society Industrial Archaeology Group who researched the cotton industry in Bollington and published their findings in Cotton Town, Bollington and the Swindells family in the 19th Century. I regret that the last of these has now been sold but copies do occasionally turn up on eBay.

Much of the historical information exhibited in these pages comes from the researches of those mentioned above with additional material from a wide variety of people, both town residents and those who have moved away, and from correspondents who have taken an interest in the web pages and provided their own information. Very many thanks to them all. The history of Radion’s Ltd. was researched and written by Ian Macwhirter to whom I am most grateful for permitting its publication here.

Much of the more recent (2010s) research into families and their houses has been carried out by Linda Stewart who was born and brought up in the town and has returned to live nearby. She has been assisted by many householders, keen to share the history of their family and property. We thank them all.

Paper industries

Rainow paper mill

Backhouse & Coppock | Tullis Russell | Slater Harrison

George Longden wrote in his Historical Report for KRIV[1] …

The paper mill was on the site of Rainow Mill [in Ingersley Vale by Mill Lane where the green shed is today], which had been a corn mill in 1611. I can find no reference to the history of the mill between 1611 and the late 18th century, by which time it had become a paper mill. The Bollington Civic Society archive includes part of a document by which Joseph Wagstaff granted permission to George Antrobus to dam the stream above Antrobus’s cotton mill [Higher Mill], provided that the level of the water was not raised above that at the bridge “near the said Joseph Wagstaff’s paper mill” (10). The document is undated, but probably dates from the early days of Higher Mill, which was founded in 1789 or 1790 (see below).

The Rainow land tax returns describe Rainow Mill as being in the ownership and occupation of Joseph Wagstaff between 1794 (the first year in which the returns name the properties being taxed) and 1796. From 1797 to 1802 (the last year in which properties were described) it was owned and occupied by Lawrence Wagstaff (11).

A deposition of 1806 by a Rainow millwright, William Richardson, tells us that the paper mill was converted to a cotton spinning mill in 1801 by Lawrence Plant Wagstaff and his partner William Watts (12).

References:

10. Kenneth Cameron, ENGLISH PLACE NAMES, 1961

11. Jane Laughton, SEVENTEENTH CENTURY RAINOW, 1990

12. Walter Smith, RAINOW IN THE OLDEN TIME, articles in the Macclesfield Courier, 1932-3

Backhouse & Coppock Ltd

This company of paper makers was founded in Castleton, near Rochdale, by Major George Backhouse. In 1876 they moved the business to Bollington, but I don’t yet know which mill they occupied. George Backhouse and his family lived in Shrigley Road, which suggests that his mill was at this end of the village. While here Major Sidney Coppock joined Backhouse in partnership and the company name changed. Later the Major’s son Lieutenant Colonel Henry Backhouse (born 1873 near Rochdale, died at sea off Crete, 30th December 1915) and stepson Mr George H Mason joined the business. They then moved the business out of Bollington to Pickford Street, Macclesfield, and later still to Sutton Mill in Oxford Road, Macclesfield. See Macclesfield Reflects![]() for more information about the life of Henry Backhouse.

for more information about the life of Henry Backhouse.

This company specialised in coated papers and pasteboard. It would be interesting to know whether this firm actually made paper in Bollington or whether it took in stock and further processed it. Paper making requires a great deal of water and I suspect that our rivers would not have provided sufficient for such a process.

The main products were embossed, fancy and enamelled papers and cards. Very similar, in fact to the products of the two paper coating companies in Bollington today – Tullis Russell and Slater Harrison. It is interesting to note that while these latter two have been in Bollington a long time, they were not the original paper coating businesses in Bollington.

As we say, what goes around comes around. In 1926 Backhouse & Coppock were taken over by the Inveresk Paper Co., of Edinburgh, who were at the time accumulating many small paper companies in order to consolidate and dominate the industry, together with a number of paper users such as newspaper and periodical publishers. Backhouse & Coppock continued to operate at Sutton mill in Macclesfield until April 1981 when Inveresk advised that they intended to close the Sutton mill business. A smaller and more versatile business, named Coated Papers Ltd. (CPL), was drawn out of the staff and processes at Sutton mill and established in the disused Brittains paper mill at Cheddleton, near Leek. In February 1984 CPL was bought out by Tullis Russell, so re-establishing their connection with Bollington! An aside – Shrigley Dyers established for more than 60 years in Higher mills also, in the late 1990s, relocated to part of Brittains Cheddleton mill!

Tullis Russell

Lower Mills (pictured below) is the home of Tullis Russell![]() (TR), one of the major employers in Bollington. This employee owned company, actually based in Scotland, takes in paper and card stock and processes it to add coatings for a wide variety of purposes. For example, they apply the glue to the back of stamp paper which is supplied to many countries all around the world. In 1984 TR acquired Coated Papers Ltd. of Cheddleton – see section above.

(TR), one of the major employers in Bollington. This employee owned company, actually based in Scotland, takes in paper and card stock and processes it to add coatings for a wide variety of purposes. For example, they apply the glue to the back of stamp paper which is supplied to many countries all around the world. In 1984 TR acquired Coated Papers Ltd. of Cheddleton – see section above.

Slater Harrison

The present company was established in 1929 (company history![]() ). Today they are housed at Lowerhouse Mill at Lowerhouse. They process paper and card stock by adding coloured coatings, often shiny or fluorescent, particularly for the retail display industry – promo boards and signs in shops.

). Today they are housed at Lowerhouse Mill at Lowerhouse. They process paper and card stock by adding coloured coatings, often shiny or fluorescent, particularly for the retail display industry – promo boards and signs in shops.

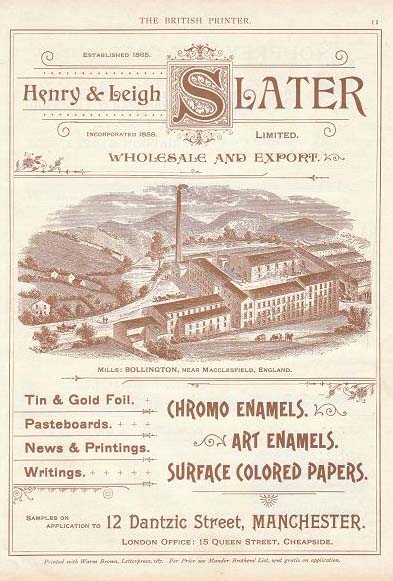

An earlier company, Henry & Leigh Slater, was incorporated in 1888, and were located at Lower Mills, where Tullis Russell are today, around the turn of the 19th and 20th centuries. See below their advertisement from the British Printer magazine of the late 19thC showing a fine engraving of the mill at the end of Church Street. There is some artistic licence in the form of the surrounding hills!

Reference

- Kerridge Ridge & Ingersley Vale, An Historical Study, George Longden, 2002.

The study document (PDF)

Your Historic Documents

Please don't chuck out those historic documents and pictures! Find out why here.

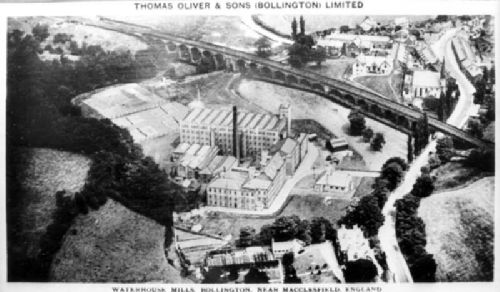

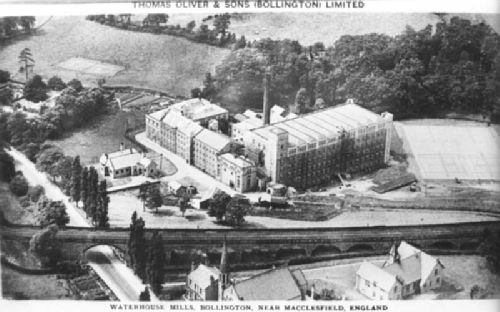

Waterhouse Mill

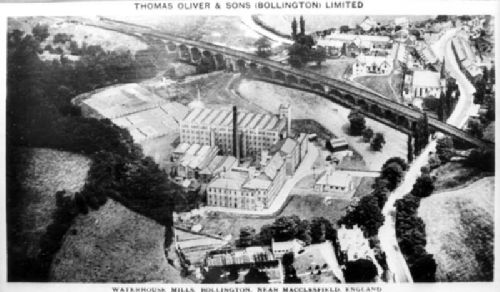

Waterhouse mill was first built by 1791 by Peter Lomas (pictured below). It didn’t survive many years, being burnt down in 1800. It was rebuilt and became the premier fine cotton mill in the country.

Waterhouse mill was first built by 1791 by Peter Lomas (pictured below). It didn’t survive many years, being burnt down in 1800. It was rebuilt and became the premier fine cotton mill in the country.

Cotton spinning ceased on 5th August 1960 and most buildings were demolished in 1962, leaving only the single story office used for 50 years since as the reception office, the recreation pavilion and a small shed.

Modern buildings were then erected on the site for Kay Metzeler who made foam blocks for the motor, aircraft, furniture and other industries. The foam was used for components such as seats. Kay Metzeler closed their mill by the end of 2012. The site was then sold to Bellway, housing developers, who obtained planning permission and started construction in early 2014. In readiness, contractors demolished all buildings on the site and all the underground remains of the original mill were dug up and removed. More than 10,000 cubic metres of fill were brought in from the tram construction project at Manchester airport to raise the ground level, ensuring that the new houses are well above the possible high water level of a flooding river Dean.

The mill was originally water powered using a large wheel. Water was extracted from the river Dean at the weir behind the end cottage (23 Adlington Road) alongside the Recreation Ground. The water passed along a wide leat, under the railway viaduct (though the leat came before the railway), into a mill pond, which has long since been filled in (see the picture above). The water drove a c.23ft diameter wheel between 9 and 10 feet wide – a substantial wheel. The used water was then routed through a long sough (culvert) to the river, near to Garden Street bridge. During the demolition of the modern buildings, the original wheel pit and the sough were all removed.

The mill was originally water powered using a large wheel. Water was extracted from the river Dean at the weir behind the end cottage (23 Adlington Road) alongside the Recreation Ground. The water passed along a wide leat, under the railway viaduct (though the leat came before the railway), into a mill pond, which has long since been filled in (see the picture above). The water drove a c.23ft diameter wheel between 9 and 10 feet wide – a substantial wheel. The used water was then routed through a long sough (culvert) to the river, near to Garden Street bridge. During the demolition of the modern buildings, the original wheel pit and the sough were all removed.

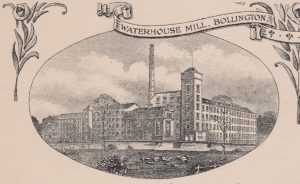

The engraving above is an artist’s impression of the mill in the 19thC. The point of view lies approximately where the Arts Centre driveway is today, so the view must have been taken before the railway was built in 1868. The image clearly shows the mill pond (light stripe across the middle) and dry land this side of it (click on the image for a bigger view). There may, of course, have been some artist’s license incorporated into such details! The image comes from a Thomas Oliver & Sons invoice dated 1914. It was common in the 19th and early 20th centuries to include images of company properties, mills, factories, on headed documents.

The best history that we have of Waterhouse mill was discovered on eBay and acquired for the Civic Society. The transcript follows …

—— Editor’s introduction ——-

—— Editor’s introduction ——-

The following material on Waterhouse mill and the firm of Thomas Oliver & Sons Ltd. is taken verbatim from the History written by the Revd. A. C. Oliver. This has been transcribed from the original handwritten pages (right) by Jaqui Parker to whom I am most grateful, with subsequent editing by myself, the webmaster. There were a few words that we could not determine and these are shown as —–. Very few changes have been made to the words and only where clarification is required and these are marked by curly brackets {}. Comments in round brackets () and gaps in the text ____ are those of the original author. Web links have been added where additional information can be found elsewhere. There is extensive use of pre-decimal currency. For those unused to this please see the Wikipedia guide![]() .

.

The pages came to us in a loose leaf file, un-numbered and not necessarily in the sequence intended by the author. I have therefore ordered them to provide, in my view, an appropriate flow of the story. The pictures referred to in the text were not provided with the text. I have therefore included a selection from the Bollington Civic Society Discovery Centre historic picture collection.

————————————

Thomas Oliver & Sons (Bollington) Ltd.

Notes, Compiled by Revd. A. C. Oliver

on the History of the Firm during 150 Years, dated February 1940.[1]

One hundred and fifty years of Fine Cotton Spinning

Forward

Sometimes the growth and scope of one enterprise may be seen more clearly by comparison with another which has grown up during the same period of time. We shall generally find that the same principles, energy, courage, resourcefulness, and perseverance have been at work in each case to bring them to whatever success they may have attained.

At the time of writing, celebrations are being held in Australia, on the hundred and fiftieth anniversary of the founding of its first Colony in New South Wales. So we may take the rise and growth of that part of the British Empire, known as Australia for a comparison. For the Firm, known as Thomas Oliver and Sons, was founded almost at the same time as the first Emigrants settled in New South Wales. A simple record of achievement is the best answer to the question, “What has been done in those 150 years”?

In both the Colony and the Firm, we have a Community of Britons, facing an unknown future, with openings for trade and commerce as yet unexplored. We find difficulties, and obstacles, seen and unforeseen, to be faced with courage, wisdom and patience. These are opportunities for expansion, work seized with faith, foresight and resolution,. There are mistakes and “set backs” to be corrected and overcome. These conditions and principles are at the base of both enterprises, and have been at work during the slow passage of the years.

We look at the beginnings of a little business, in a little mill, driven by the waterpower of a small stream from the peakland moors. Again, we see a few settlers, among the rocks, scrub, and gullies round Sydney Harbour. And then we shift our view, with speed of thought, through the years, to the great self-governing Dominion, and see it the centre of Government of a continent. Again we look, and see the change brought about through the years, to the modem factory with the latest equipment of power, machinery, and transport, but now amalgamates into one great Association of Firms under our central government and direction. And we are forced to the conclusion that those tremendous forces of the human spirit, courage, perseverance, sagacity, and patience have been at work all through, till, at last, both enterprises, Colony and Firm stand where they are today.

All this could only have been done by the co-operation of “all hands”. In both, Colony and firm, there must have been a willingness to adapt and re-shape in the face of new conditions and circumstances. And each entity, the Colony and Firm, have kept its own individuality. The early Colony may have been merged with others, as they have sprung up, into the Commonwealth of a great Continent. The Firm may have been amalgamated into one great “Association of Fine Cotton Spinners and Doublers”. But each concern retains its own individuality, which contributes to the success of the whole. Both Colony and Firm have been listed in the hundred and fifty years of their existence, by those “two impostors success and failure”, and have learned how to “treat them both the same”, as Rudyard Kipling, the great poet of Empire, has it. There has been the early flush of success and expansion, (by the discovery of the goldfields) on the one hand, and there have been lean years, some filled by wars and loss, and even famine. And yet, with that instinct for righteousness, which is the strength of all, both have emerged to celebrate a great achievement and with that vigour and strength which are still needed, when Empire and Nation, Colony and Firm, may need all the resources of mind and body, to face the constantly shifting problems of the world today. We may close this introduction with some lines of the poet Whittier (a few words altered)

“But through the drive

“Of its loud life, hints and echoes of the time behind steal in;

“And love of Colony and nation, E’en the factory’s humming rhyme

“Point the path of truth and duty to each true man of the time”

The rise of the Great Republic of the U.S.A. began at the same time as the Firm, and the Colonies of Australia. Its growth was, of course, marked by the same qualities of courage, tenacity of purpose and perseverance as they were; but I have preferred to take the British Continent of Australia as a parallel for the history and progress of the Firm.

A. C. O.

The History of Bollington and the Mills

Bollington is a parish in the Forest of Macclesfield and in the ancient Parish of Prestbury, which at one time included even Macclesfield. Strangely enough, the River Bollin from which it most probably derives its name, does not come nearer to it than two miles, and it is really situated {on} a little river called the Dean. The village lies in a lovely valley, at the foot of the hills rising into the Peak District of Derbyshire.

An undoubted Roman road is marked on the map in Codrington’s “Roman Roads {in} Britain”, running from Manchester, through Levenshulme (this part is still called “High Street”) and on to Stockport and Hazel Grove. From there it went on to Aquae (Buxton). The historian Whitaker mentions a Roman road going on through Adlington, and an old ordnance map shows a “Roman Road” going over Billinge, in which case, Bollington has a connection with the times of the Roman occupation of Britain. In any case, before the Macclesfield canal was brought through the village in {1831}, or the Railway in 1870, it was partly along the Hazel Grove to Manchester road that loads of raw and manufactured cotton were carried by horse and cart, at a cost of from 4/- to 6/8 per load.

In 1353, the Manor of Bolyngton was in the hands of the Black Prince. This passed on to Queen Isabella, and she granted the mill of Bolyngton to William de Shirborne for life. He enjoyed this only a few months, and then the Black Prince granted it to Robert of Plumstoke his yeoman and barber for life. It then passed to William Soty a yeoman for life.

These were troublous times, and in 1354 this mill was nearly in ruins. However, in 1358 the Black Prince visited “his manor and mill of Bolyngton”, and he ordered the gift of “two oaks fit for timber, from his Forest of Lyme”, to William Soty for the repair of his mill of Bolyngton”.

Bollington Hall is near to where this old mill was situated {The mill referred to above was almost certainly that which stood in Ingersley Vale on the site of Rainow mill before that was built. The corn mill behind Bollington Hall Farm was built in the 16thC}. And in the passage of time it is believed that Elias Lomas and his brother Peter Lomas (b.1750 d.1822) {right} came to live there. Near by there was a tanyard owned by the two brothers on the site now occupied by the house and garden known as “Brook House” But after some years, they saw the possibilities of another business which was springing up in the North of England – cotton spinning. At the other end of the village there was an old building, which had been a brewery, as far back as 1662 {but we are very unclear about which building or where this might have been}.

Bollington Hall is near to where this old mill was situated {The mill referred to above was almost certainly that which stood in Ingersley Vale on the site of Rainow mill before that was built. The corn mill behind Bollington Hall Farm was built in the 16thC}. And in the passage of time it is believed that Elias Lomas and his brother Peter Lomas (b.1750 d.1822) {right} came to live there. Near by there was a tanyard owned by the two brothers on the site now occupied by the house and garden known as “Brook House” But after some years, they saw the possibilities of another business which was springing up in the North of England – cotton spinning. At the other end of the village there was an old building, which had been a brewery, as far back as 1662 {but we are very unclear about which building or where this might have been}.

This they rented, and established there a business which, not many years after, became known as “Thomas Oliver & Sons,” for Thomas Oliver in the year 1817 married Mary Lomas {This was the second Thomas Oliver b.1786 who married the daughter of Peter Lomas. The business was established with the first Thomas Oliver b.1756}.

On July 23rd, 1838, Thomas Oliver bought from Thomas Creswick, Samuel Rodgers, and Mary Creswick, for £6,000, the land on which the Waterhouse Mill was built, and the land for the Reservoir by means of which the Waterwheel was driven, also “The Waterhouse” and fields adjoining, as far as the boundaries of the Estate of C. R. B. Legh Esq. of Adlington Hall. “The Waterhouse and a large garden” were there in 1838 and Thomas Oliver lived there. Except the south end of the house, this was rebuilt, and my uncle enlarged by his son Thomas Oliver in 1870. He married Maria Creswick, daughter of James Creswick, of {Crookesmoor}, Sheffield, on Oct. 4th 1862. James Creswick was a partner in the local firm of Thomas, James and Nathaniel Creswick, which was the pioneer of the silver plating industry.

Editor’s note —— I don’t know where the author got the value £6,000 from, but this seems a lot for ‘the land’. It also included “The Waterhouse” – was this the domestic property we know as the Waterhouse today or was it the mill, or perhaps both? This was the equivalent of £580,000 in 2013, so I suspect it was paid for the land and the house, and possibly the mill.

There is a deed in the possession of the Fine Spinners Association dated 1774. This is a statement of land settled on Mary Creswick, a daughter of William Creswick, Gentleman, of Little Padfield, Glossop, Derbyshire on her marriage on Sept.12, 1774 to Peter Lomas. Farsighted, bold and wise management characterised the conduct of both these families, who were respectively engaged in the silver plating and cotton spinning industries. And perhaps these characteristics still further blended and re-acted to the advantage of both families and firms, for some years after, Thomas Creswick married Mary Oliver; and Phoebe Ann Oliver married James George Antrobus Creswick of Ecclesall Grange, nr. Sheffield, also, as above mentioned Thomas Oliver of the Waterhouse, Bollington married Maria Creswick, daughter of James Creswick of {Crookesmoor} in 1862.

The Firm of “Thomas Oliver & Sons” began, in what was known as “The Bollington Mills” i.e. the “Higher Mill” formerly a Brewery, and the “Lower Mill” afterwards a paper mill. These were leased from Mr Harrop of Stockport, a solicitor and Mr Creswick of Sheffield, also a solicitor.

But about 1838, “The Waterhouse Mills” were built {see note below this section} and the activities of the firm were removed there. In these lovely rural surroundings the mills were erected and the business carried on. The sheltered position was most favourable for fine cotton spinning, and contributed not a little to the high quality of the yarns afterward spun there. The little river Dean ran by the mill and at the foot of the gardens of the Waterhouse and Brook House. This was conducted by a “flume” to the waterwheel which supplied the power for driving the machinery of the mills. Pheasants, hares and rabbits can still be seen from the mill windows; and until the advent of the dye works and bleaching works at the top of the village the river was a trout stream of note. Mr. James Creswick who married Miss Phoebe Ann Oliver is said to have caught a splendid dish of trout for the wedding breakfast at 4a.m. on his wedding day!

Editor’s note —— There is some discrepancy between the date given here for the first construction of the mill at Waterhouse – 1838 – and the date found in other documents giving 1791 for the same. The earlier date, 1791, is actually the more likely with the later date, 1838, being that of an expansion of the mill following changes in ownership. If the mill at Waterhouse had not been built until 1838 it would probably have been steam powered, so obviating the need for a water wheel and its associated works. Further, the Macclesfield Canal had been built by that time along with Clarence Mill and the success of the latter would have shown that down by the riverside was definitely not the place to build a new mill, but higher up the hill beside the canal!

“Swindells & Oliver” “Oliver & Swindells”

A partnership of “Swindells and Oliver” existed from Nov. 12th 1832 – Nov. 12th 1842 when it was dissolved by mutual agreement and a certain amount of “coolness”. This was renamed as “Oliver and Swindells” in 1847, but there is no record of when this was terminated. Probably it was when the “Adelphi Mills” were built {in 1856}.

The Earliest Records of the Firm

The earliest source of information about the Firm of Thomas Oliver & Sons is contained in a ledger commencing August 3rd, 1790. But this shows a business already in being. There are items for repairs of buildings, and also of machinery. There are records of the installation of used machinery, but those are to keep pace with the invention and use of larger and better machines, especially for carding and spinning. For instance, in 1790 the firm of Randle Astle (?) were paid £57-15 for 11 Jennys at £5-5-0 per Jenny. Thomas Leeming of Salford £54 for 2 Carding Engines, Thomas Daniels £14-14-0 for “a new card” 3/6 for a “Rap” Reel and for 69 Jennys at £6-6-0 £454-14.

19 Reels at £1-10. £28-10. Counters & desks £2-2 and for skips £60. From Joel Needham of Stockport in the same year was bought “a new spinning hub 216 spindles at 6/3 per spindle, £70” and “a Drawing Frame” £30.

Later in 1792, there were bought 38 pairs of washers and doffers £17.14,10. A box of cards, the 5 inch doffers £21-17-4. In 1793 By Jenny Strings £1-11. By Billy Strings £2-12-0. In 1797 Mr. Amos Mellor “By making Jennys & Repairs £53-17”. In 1799 Thos. Ashton. By a new Mule 252 spindles at 4/9 £59-17. By W. Meek, Buffalo Hydes £8-18-1. By Mr. Garside, Stretcher £20. 2 Horses £50. Geo. Swindells, Bollington (among other things) drumbanting £34-4-1.

In 1801 To a new spinning mule £60. By work done for waterwheel £14.12.11. In 1802 1 Carding Engine £30. To Philips, Wood, and Wilkinson, Stockport, new spinning mule, 216 spindles, £70. Do. at 5/5 per spindle, £57.7.

A new reel, £2-5. 1 Drawing Frame £30., in 1806 5 Card & Engines, £64.

Insurance of Mill & Machinery

| 251 1804-5 {251 refers to the page or section in the account book} |

£ |

|

| Mill |

450

|

|

| Waterwheel |

50

|

|

| Millwrights work including all gears |

50

|

|

| Clockmakers work Carding & Breaking Engines and all movable utensils |

300

|

|

| Stock Cotton in ditto |

100

|

|

| Stores |

30

|

|

| Stock in ditto |

20 |

|

|

£1000 |

||

| Insured in Phoenix Fire Office (there is no date for this entry, but as it is on the last page in the ledger it is most probably 1804-5). |

||

| An estimate of machinery in B L factory. | ||

|

£

|

||

| 19 mules |

1110

|

|

| Mill |

700

|

|

| Waterwheel Cistern & Running Gear |

375

|

|

| 9 Carding Engines |

540

|

|

| Puker |

36

|

|

| Batts Frame |

40

|

|

| Draws & Rov.s Frames |

94

|

|

| Cases for 2 sets |

30

|

|

| Stock of Yarn & Cotton in Mill |

55

|

|

| Straps Skips etc. |

20

|

|

| Total £3000 | ||

| (an abridgment of the above appears below) | ||

| Mill |

700

|

|

| Waterwheel & Running gear & Cistern |

395

|

|

| Machinery & Clock Makers work |

1850

|

|

| Stock & Straps etc. |

75

|

|

|

Total £3000 |

The Ledger of 1790

This is a book, strongly bound in “suede” leather of 500 pages. Even after 150 years is still almost perfect in its condition. The book itself tells its own tale of foresight and determination. For it must have cost a considerable amount in those days and those who bought it had evidently an ambition and outlook beyond the comparatively small business for the recording of the transactions for which it was originally purchased.

Throughout it is beautifully kept, the writing is “Copperplate” in character, and there are very few erosions or mistakes. The spelling is often quaint. “Pottatoes”, “By Comishion”, “Spining”, “Braught Fod” “A Riem of paper”, “Candels”, “Mahogony”, “oile”. This last is spelt incorrectly and also correctly, according to modern usage as “oil” on the same page; also “att” and at. But these spellings and variations are not surprising for in those days, people often spelt phonetically. As has already been pointed out, the book seems to show a business already in being, before the date of the first entry, August 3rd, 1790.

There is a Register of the Parish of Fretherne Gloucestershire, of which has Mr. A. C. Oliver was Rector, of about the same date. In this, the name of a man called “Tykel” is spelt in eleven different ways, and three of these variations appear on the same page, and in the same handwriting!

Extracts from the Ledger of 1790 – 1805

1790 By “Comishion”

1792 To “Spinning” 172lb at 14d per lb.

” Mr. Philip Antrobus 2 doz of 13s Haks. Att 22/-

” To Iron & Brass & 2 Bank Notes, £4-7-5½

” Wm. Gosling To 3 Bank of England Notes £3-0-0

1793 Wm. Cartwright, Sadler, Macclesfield.

A Bill for Straps and Sadling

” Joseph Frost, Macclesfield, By Candels £4-15-0

May 12 1794 One Years Rent for 5 houses in Bollington £12-18-0

1794 By Carriage of 8 cwt of Cop —- to Manchester 6/8

” To oile 3½ pints 2/7½

1795 To Saml. Hatton, Macclesfield,

18 baskets of coal, & carrying £1-1-0

” To amount of Goods Braught Ford.

(This for the spelling!)

” By ¼ Pew in the new church £20-0-0

1797 1 Riem of Paper 36lbs at 4½, 13/6

1798 By various purchases of candles

(these were in the autumn & winter months.

Does it show the illumination of the mill in those days.)

1798 Joseph Wood, rent of our room for spinning

of cotton, @£40 p. annum

1799 Thos. Sutton, One House, @£2-8-0 per year.

Sept 29 1800 To rent for Tanyard £25.

1800 Richard Corliss, Blackburn, Mohogony

Chamber stool, £3-3-0

1800 By ten years rent, for Fastening the Weir

to the Swinewood Field at one Guinea per year £10-10

1801 Edward Douman Esq, Shrigley. To Hay £10-17-6

1802 Timber, 184 feet at 9d

” 1 Skip, Italian Lambskins £3.

” Thos. Hadfield, Druggist

By 9 Gall 5pts Pale Oile @ 5/- £2-8-1½

April 13, 1802 To Team to Blackburn £4-4

April 16, 1802 To bringing Horse & Chaise back 5/-

” Carr. To Flash 1/6

” By One Pipe of Rape oil £30-16-0

1803 John Upton Macclesfield

” By 2 gallons of Neatsfoot oil & 1 lb of glew 12/10

” By ½ a cow hide £1-17-6

” By ½ a hide of white leather, 15/-

” John Latham, Rainow, to Horse Beans 16/6

” Geo. Antrobus 2 pecks Pottatoes 2/6

” To A Horse to Manchester 4/-

1804 Richd. Hemming, Worcester, 2 Barrels

of Cyder, £9-14-8

252 The following quaint entry appears on the last page of the Ledger.

“An excellent Drink for a horse for swell’d legs. Take half pound of honey 4 ounces of liquorice powder 4 ounces of Carraway seeds one ounce of grains of Paradise all well powdered together to be given in a quart of warm ale.”

There appears in 1804 two short letters to Mr. Peter Lomas pressing for payment of a/c showing that the firm was not exempt from troublous times and shortage of Capital, but weathered the storm.

There do not appear to be any books or documents showing the progress of the firm after 1806. Possibly these were lost or destroyed when the new offices were built. The finest counts which were spun as shown in the old ledger were from 8s to 60s. but it is certain that the Firm kept abreast of each new demand for ever finer counts. A large and handsome new mill, running at right angles to the earliest buildings, was built, and spinning mules of from 1400 to 2600 spindles in a pair were installed. A large and powerful beam engine drove the machinery, carding, combing, slubbing, intermediate, moving frames, and several thousand doubling spindles in the lowest storey. This engine was coupled by a shaft under the road to the waterwheel.

About this time the lace trade grew into a large industry, and this led to the Firm specializing in ever finer counts, and a large trade chiefly with Nottingham, but also with Brussels, Calais, St. Quentin’s and other places on the Continent. By 1860, the counts spun were from 140s to 220s, in two and even three different qualities x, xx, and xxx. As already mentioned, in 1862, at the time of the American Civil War, such foresight was shown, that enough cotton was bought and stored to carry on work during that time, which brought such trouble and suffering to most of the Lancashire cotton trade. This helped considerably to bring the village of Bollington through this very difficult crisis. In 1886 the counts rose to no less than 420s. this order was repeated before each Jubilee of the late Queen Victoria, and the Coronation of King Edward VII so it is probable that the output of this count 420s was used for some specially fine lace for these great events.

Ring doubling was introduced in 1885-6 and this enabled the firm to deal in counts from 80s upwards. The firm has always kept abreast of new demands and markets arising from the invention of new fabrics. Some of these were for white bleached thread and softer and —-urized twists for mixing with silk. So rapid were these changes and demands that, whereas in 1881 only about 30 varieties in count and qualities were produced, in 1887 the firm was dealing in over 100.

In the Great War 1914-1918, a great deal of the thread for the material for making the wings of the aeroplanes then used, was spun at the Waterhouse Mills. This was used both in England & France, & Mr. E. L. Oliver had several journeys to the Continent during the War, to ensure that the thread was up to the standard of strengths required for this purpose. As may be here mentioned that two of Mr. E.L. Oliver’s sons served in the War, Mr. Ian M. L. Oliver with the South Staffordshire Regiment, and was wounded at Kemmel Ridge, and Mr. Gordon Oliver with the French Army.

It will be within the knowledge of many people, (especially, perhaps, the ladies!) what beautiful and charming fabrics have been during —- bad years brought out for dresses, stockings, curtains etc. etc. and the firm has always kept abreast and even in the forefront in this matter.

The Trade Mark, “The Happy Valley” has been registered to describe many of these products which have a wide range of various fabrics the last English team of Cricketers which visited Australia was presented with shirts of beautifully soft texture, woven from cotton spun by the Firm, and many of them wrote to express their appreciation of the usefulness and comfort of the material.

From the foregoing it will be gathered that wise, orderly, and courageous advance has marked the progress of the Firm of Thomas Oliver & Sons through the century and a half of its existence. And there is every reason to hope that these qualities will be manifested in the years to come; and that the Firm of Thomas Oliver & Sons, will continue to contribute to its own prosperity and that of the Fine Spinners Association of the village in which it had its rise and progress through the years, and incidentally therefore to the Cotton Trade of England.

By wisdom and foresight the firm laid in a stock of cotton sufficient to carry on through the American Civil War, and the resulting cotton famines, which caused much distress in the village.

Editor’s note —— The history omits to mention that in 1898 Thomas Oliver & Sons became a part of The Fine Spinners & Doublers Association which was set up to enable cotton mills to trade collectively and benefit from the increased scale and, no doubt, reduced competition! Beyond the scope of the history it can be added that by the 1950s the company was suffering from the effects of depression in the industry and the mill closed for the last time on 5th April 1960. It was largely demolished in June and July 1962 to be replaced immediately by a modern industrial building for Kay Metzeler, which has now also gone, to be replaced by housing.

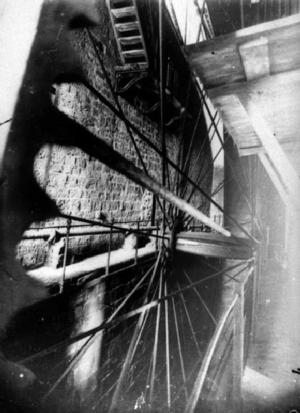

The Waterwheel & Engines

The driving power for the first mills, the old Brewery, and the Paper Mill was a waterwheel. When the business was removed to the Waterhouse Mill, at the other end of the village, the same method of driving the machinery was employed again the foresight and courage and wide range of vision for the future of the firm was evident. For the water wheel installed was the third largest in the Kingdom {see note below this section}. The second largest was also in Bollington, at the Bleach Works at Clough Vale. The largest of all was that at the Great Laxey Mill in the Isle of Man.

The “Flume” was led from the little River Dean to a large reservoir, so that there was almost always, except in abnormally dry seasons, sufficient head of water to drive the wheel.

As the business expanded, even this did not give sufficient power; so a fine “Beam Engine” was installed. There was a shaft in a tunnel under the road to the mill, by which this could be coupled up to the waterwheel, if desired. In 1906 both of these were done away with, and a powerful horizontal engine by Messrs. Musgraves was installed. This was started by Mrs E. L. Oliver and was named after her, “Florence Adelaide”. The boilers in the Engine House were also, naturally, renewed and brought up to date, from time to time, to keep pace with the ——— and alterations in the engines.

{Editor’s note —- this claim (third largest wheel in the Kingdom) must be regarded with some doubt. Inspection of the site shows that it would be difficult to obtain a great height between the leat and the level of the river below Garden Street weir. This view is supported by evidence given in a Chancery Court case of 1806 in which it was said “… that the head of water afforded is three feet and the diameter of the wheel turned by it 23 feet.” While a big wheel, this was unlikely to be third biggest. I have also discovered that there was a wheel at a mill in the village of Diggle which was actually the second largest in the country, making that at Clough mill the third largest.

December 2013 update – Clearance of the site has resulted in exposure of the remaining stonework of the wheel pit. The lower half was below ground and was about 12 feet deep, therefore the wheel would have been between 23 and 24 feet in diameter. The pit was just less than 10 feet wide. The wheel would have been top fed, and it rotated clockwise (viewed from the road), discharging the water down a very long sough (culvert) which ran from the bottom of the pit several hundred metres across the site, under the gardens of the Medical Centre and Brook House, to enter the river Dean below the weir by Garden Street bridge. This sough was beautifully constructed of semi-dressed and free stone and measured (in the first 100m) about 6 feet wide by 4 feet high. This was a surprise because we expected it to quickly become higher and narrower (stronger that way). However, it had a very shallow fall (to maximise the wheel size) and the need to discharge the used water quickly enough to prevent backup, which would slow the wheel, could possibly have been a consideration in its design. The sough was built in a 4 to 5 metre deep trench cut through solid red sandstone – an enormous undertaking for the 1780s. Indeed, the rock faces immediately behind the stone walls of the sough would have provided the lateral support required by the curved roof. At no point across the site had there been any collapse of the sough, a great credit to its builders.

The surveyors who, in 2011, prepared the drawings for the house building planning application carried out soundings across the site so as to note the underground structure. They, rather worryingly, recorded a geological fault line across the site – it turned out to be the drainage sough! Far from being a fault, the ground is solid rock, with a trench cut across it!}

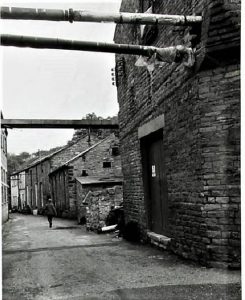

The Mechanics Shop

The Waterhouse Mills were furnished with a very well equipped mechanic shop. Lathes for both wood and metal, blacksmiths’ shop and a staff of mechanics and carpenters dealt with a very large range of not only repairs, but alterations of machinery. John Oldfield (foreman) W. Goodwin, J. C. Walker were some of the employees there.

A blunderbuss hung on the walls of the shop. This weapon was still in its place up to 1900, but about that time it disappeared. Other mills in the village were similarly armed against any attempts on life or property. The use to which it might be put for this purpose may be illustrated by an incident which happened at Messrs. Swindells’ Mill. A new watchman, an Irishman, was engaged and Mr Martin Swindells gave him many other instructions for his night duties; that if he heard any suspicious noises he was to shout three times, “Speak, or I’ll shoot”. Mr. Swindells did not quite trust the pluck of the new man, so to test it, he hid himself behind some barrels and packing cases. When the man came round, Mr. Swindells set up a violent commotion in his hiding place. The Irishman yelled out “Shoot or I’ll Shout three times” and let go in the direction of the noise. It was fortunate that Mr. Swindells was well hidden so he escaped injury.

The Great Flood of 1872

A great flood visited the village in the week June 18-25, 1872. A thunder bolt fell in the field, just across the river at the bottom of the Waterhouse gardens. This made a considerable hole, like a large shell hole in the Great War. Damage to the extent of £7000 was done in the Raw Cotton Store, and in the Doubling Rooms. Cops were carried into the Waterhouse gardens, and gooseberry bushes were covered by them far more effectively than if they had been purposely entwined by cotton to keep off the birds. Many years afterwards, when some doubling frames were dismantled to make room for new ones, traces of silt from the flood were found inside the rollers which drove the spindles. The flood ran into the Waterhouse, at one door, and out at the other, across the hall, and men were employed making banks of turf and clay to stop it from spreading to the rest of the house. Much damage was done in the rest of the village, but the Waterhouse Mills suffered the worst. This low lying and sheltered position in the valley, though excellent for the prosecution of the fine spinning industry, exposed them to the worst ravages of the floods.

Members of the Firm

|

Peter Lomas, born 1750, died 1822. Thomas Creswick Oliver, the son of W. C. L. Oliver, only had a short connection with the business, from 1875 to 1879. On Jan 3rd, 1883 he became a member of the Manchester Stock Exchange. In 1933 he became the oldest member, and was made an Honorary Life Member. He died six years afterwards in {19 April} 1939. Alfred Creswick Oliver {author of this work}, son of Thomas Oliver was a member of the firm from 1879 to 1887 when he went to Oxford. In 1890 he took Holy Orders, and after serving in four curacies at Pilling {and} Middleton in Lancashire, Wirksworth in Derbyshire, and Eccleshall in Staffordshire, became Vicar of Barlaston, Staffordshire, in 1902. In 1918 he became Rector of Fretherne, by the river Severn in Gloucestershire. Edmund Lomas Oliver, 2nd son of Thomas Oliver entered the Firm in 1882. On Jan 3,1899 it was incorporated in the Fine Spinners & Doublers Association Ltd and of this he became a Director in —-, a position which he held till his death in 1933 {Doubts over this date; genealogy says 26 Jul 1953. However, note that the text was written in 1940!}. Percy Creswick Oliver third son of Thomas Oliver entered the firm in 1884. He died in ____. Ian Maurice Lomas Oliver, son of E. L. Oliver, entered the firm in ____. He served through the Great War, with the South Staffs Regiment and was wounded at Kemmel in April 1918. He joined the firm in 19__ and in ____ was made a Director of the Fine Spinners Association. Percy Gordon Oliver, second son of E. L. Oliver, served in the French Army in the Great War. In 1918 he joined the Firm. {Editor’s notes: Edmund Lomas Oliver is pictured twice (left and below), once in his younger years and again in his older years. The Creswick family are better known for inventing, at their premises in Sheffield, the process known as silver plating.} |

|

|

|

|

|

|

|

{Acknowledgements}

I am indebted to the Revd. R. N. Betts former vicar of Bollington, author of the “History of Bollington Church” for many of the particulars of this history of the village. {He may have meant ‘Bollington Through the Centuries‘.}

To Mr. S. H. West, the manager of the mills at Baslow, Derbyshire, for the whole of the section dealing with the history and work and activities of the firm in that village. {This is missing from the material we have.}

To Mr. George Swindells for particulars as to the partnership of “Oliver & Swindells”.

To Mr. H. V. Snape for information about the firm and the County ___.

To Mr. H. V. Snape for information about the firm and the County ___.

To Miss Spencer of Mobberley for some of the particulars of the mill, and the photograph of it. {We don’t have the photograph.}

To Messrs. Ian & Gordon Oliver {Gordon pictured left, 1950} for much of the matter relating to recent years, and access to books and documents.

And Chiefly to the Directors of the “Fine Spinners & Doublers Association” for access to the old deeds and documents and books relating {to} the Firm.

A. C. Oliver

Mobberley

The Firm had a mill at Mobberley in Cheshire. At what time cotton spinning began there is not clear. But a bill from Messrs. Kay, Engineers, of Bury, Lancashire, was seen by A. C. Oliver about 1884. The bill was for engines to the value of £1890 erected in the mill about 1859-60. An offer for the mill property for £5000, was by a Mr. W. I. Harter, of Mobberley Hall, on April 27th, 1875. The negotiations were somewhat prolonged, but ultimately accepted, for on July 23rd, 1878, a letter was received from Mr. Harter, “To Mr. J. Oliver, Dear Sir, May I ask what was the arrangement about whitewashing the Mobberley Mill outside? Did you do it, or were the tenants Kay & Richardson expected to do it? Yours truly, W. I. Harter”. The business was after turned into a Crêpe Mill. This came to an end in August, 1887; and the mill was pulled down about 1891. Miss Spenser of Fern Bank, Mobberley, has a picture of it.

An account of travelling expenses of Mr. J. Oliver shows “Sept. 17, 1871, Expenses to Mobberley, 3/6”

An Old Agreement (from the Ledger 07/1790)

Be it remember’d it is this day agreed by and between S. Gregg [sic] of Styall [sic] in the County of Chester, of the one part and Mary Crooks and Thos Lees of Manchester in the County of Lancaster of ye other pt. as follows That ye said Thomas Lees shall serve ye said S. Greg in his Cotton Mill in Styal in ye County of Chester as a just House Servt. Twelve Hours in each of the six working Days & to be at his own liberty at all other times. The Commencement of the Hours to be fix.d from time to time by the said S. Greg, for the sum of eight years at the wages of 9d per week the first year and 1/- per Week the remainder part of this time & Mr. Greg engages to find the Thos Lees with Meat Drinks Washing & Lodging suitable to one in his station during the said term, and that if the said T Lees shall absent himself from the service of the said S. Greg, in the said working hours during ye said term without his consent first obtained, that the said S. Greg, may abate his wages in a double proportion for absence; and the said S. Greg shall be at Liberty, during ye said Term to discharge the Serv.t from his service for misbehaviour or want of employ.

As written {by} their hands this 12{th} Day of July {17}96

| It is agreed for Mr. Greg To receive his Wages & Find him with Clothes |

Mary Crook Thos Lees |

Spelling

1lb of “Glew” 60 Bundels Twists. Ballance — of sundrie people

1795 1 Riem of Papers 1 Riem of Paper Law. P. Wagstaffs

115 1796 Timber Dales (? = Drals) 184 feet at 9d

1797 Dr. “Sundrie” Persons

147 1798 Joseph Wood for “Carige”

148 1798 Bateman and Sherratt Cast “Mettle” Gudgeons.

149 1800 Rent from Thos Lutman spelt also Luttman on the same page

150 1798 “Sundry” Persons

153 1799 Owing to “differant” people

155 ” “Mettal” gudgeons £1-17-2.

” ” Thomas Lomas, Jenny “Rollers”

” ” Wm. Meek, Buffalo “Hydes” £8-18-4.

153 1797 Also on page 153. Wm. Meek, Buffalo “Hides” 19/2

156 1799 “Expences” to Blackburn £1-11-6.

158 1799 William “Kirby” 40s at 3/3½ and next line but one,

” ” Wm “Kirkby” 40s at 3/7

157 1799 By “Neat” Profit £319-15

158 1799 To John Bradbury Amount “Carrige”

162 ” By Nathan Duncalf for “Pully”

165 ” To 1 saddle and plated “Stirraps”

171 1799 Lindsay 181 Linsay. Sales of Cotton.

192 ” 2 Cuppling Boxes 11/3

194 1802 John Wattson, to Glassing. 1/-

199 1801 Wm. Needham Bollington Bucles (= Buckles) & Straps

199 1801 ” ” “Lintells”

199 1801 ” ” To Glaizing” Bill 2/-

201 1802 To Ballance

201 1802 Case from Flask being “Ommited” (= omitted)

205 1803 Mr. Stuart 86 “Bundels” of Twist

215 1802 One “Barrell” Ale 18 Gall. At 10d 15/-.

220 1804 Stephen Sheldon, Bollington “Plouging, 1 day 8/-

223 1803 Geo. Harrison, Manchester “Cambric” in Aug

& in Sept (in the same handwriting) “Cambricks”

230 1803 “Blew” Skip Paper

232 1803 1 “Rap” Reel

239 1805 John Martin, Newcastle Staffordshire “Atorney”

142 1804 2 driving “pullies”

250 Sarah “Chaniler” (= Challiner)

251 S Gregg of Styal and on the 4 line of the same

Deed, “the same S. Greg.{“}

252 1798 Richd Harvey “Waist” Buyer Ashover

Nr Chesterfield

257 1804 Willm. Hatfield “Rowlar” Maker

Nr Glossop “Derbishire”

251 1805 “Movable uttensils”

Various hotels

My Father tells me how he travelled by stage coach where there were no railways. On one of these journeys to Devonshire in the winter, he described how he and his Father arrived with their beards frozen. Bills are extant from the various hotels at which they stayed. At the “Three Tuns Hotel” Tiverton, they occupied sitting room 25 and bedroom 14, as to which time there is a note that they were “The Noble Lord Palmerston’s Sitting Room and Bedroom”.

“Cumberbach’ s Hotel”, Liverpool

The “Charing Cross Hotel” (this on journeys to and from the Continent) they also stayed at the “Lord Warden Hotel![]() ” Dover.

” Dover.

These last on journeys to and from the Continent, to France, (Calais, St. Quentin, Lille), Belgium (Brussels) Germany, Austria (Vienna). At Nottingham, the Hotel usually used was the “Flying Horse“.

—— Great Northern Hotel![]() , King’s Cross London 1871.

, King’s Cross London 1871.

Queen’s Hotel, Manchester. {1 Portland Street, demolished 1974.}

St. James’s Hotel, Regent St, London.

Waterloo Hotel, 85 Jermyn St, London S.W.

That completes Revd. A. C. Oliver’s History. The remainder of this page is written by the webmaster.

Pictures

We are lucky enough to have some very good pictures of Waterhouse mill taken over a long period of time. In fact our oldest picture (immediately below) is one of the earliest in our collection, taken before the railway was built in the late 1860s.

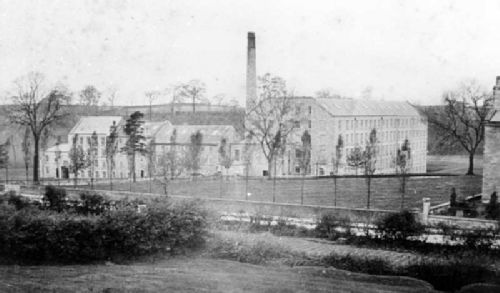

Waterhouse mill, 1860s before the railway came to Bollington. The railway viaduct that today bisects Bollington was built across Wellington Road from left to right in the centre of this picture. Notice the Methodist Manse to the right. The apparently grassy area immediately behind the Poplar trees hides the mill pond (see next picture). The presence of the boiler house chimney, suggests that water power was replaced by steam before 1869. The water wheel house remains, difficult to see, it is the lower building immediately in front of the chimney. Another feature is notable by its absence from the picture; the gatehouse, built in 1922, which existed until 2013 as the reception building for the Kay Metzeler mill. |

|

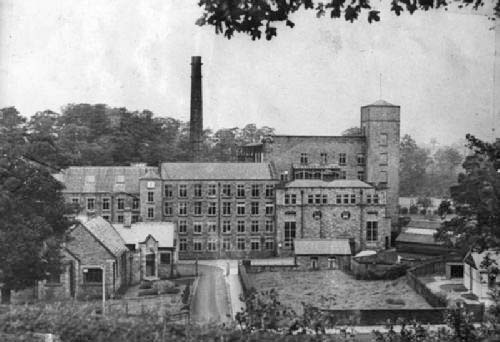

Still no reception building to the left of the entry road. However, a tower has been built on the right hand corner of the mill. This supported a water tank in the top section – to provide a head of feed for the boilers? Possibly. More likely this water was required for spray in the cotton processing rooms and possibly for toilets and basins on each floor. This tank had within it a ball cock – the ball was copper and more than 1ft in diameter![3] Bryon Holmes ‘rescued’ it when the mill was demolished – I wonder where it is now? |

|

Two pictures from the air. One might suppose that they were taken on the same day. They are both from postcards which look like two of a set. Details of the mill seem to be the same. So why are the tennis courts laid out differently – in the top picture the nets are parallel to the river, in the lower picture they are at right angles! Close inspection of the original postcard suggests that the nets in the upper picture have been hand drawn! After considering several pictures, I am also convinced that the mill pond has been extended by an artist. The picture above shows a pond taking a small part of the land – these two pictures show a larger pond with trees growing in the middle! I can’t believe that the pond was ever enlarged just as it was becoming redundant. |

|

These aerial pictures were taken in or after 1930 (the reception building was built by then). The small mill pond has now gone, although the leat remains, as it did until 2013. There have been a number of changes to the buildings along the front – compare with the two pictures above. The low building in the near corner has proved to be over the original wheel pit. The pit was exposed and removed in 2013 when the site was cleared for housing. See page on the site clearance. |

|

This picture, while looking old, was taken in the mid 20thC. The clue is the building on the extreme right which was built just before or during WWII and provided as a children’s nursery so that their mothers could go to work in the mill. This nursery continued into the 1970s before the asbestos clad building was deemed unsuitable and demolished. The reception building, built in 1922, is also shown in front of the mill to the left. Note that the building to the front right of the mill has been substantially altered as the pictures progress. |

|

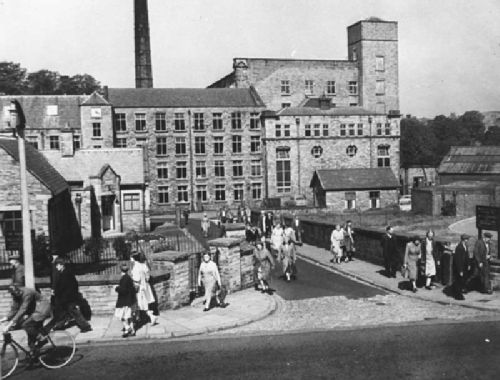

Workers leaving the mill – it says 12:20 on the clock, so this would be for lunch or maybe knocking off time on Saturday. Dated 1959, towards the end of cotton spinning; in fact spinning finished on 5th August 1960. Notice the light pattern on the end wall of the main building – compare with the top two pictures and it can be seen that the darker stonework has been added later. Further examination of the pictures shows that an additional row of large windows (see picture below), rather like a garret, was added to the sides of the main building to extend the top floor across the whole building. |

|

The end of Waterhouse Mill. It was demolished in June and July 1962 to be immediately replaced by modern industrial buildings for Kay Metzeler. The latter closed their business here in 2012 and the site was cleared in 2013 ready for the construction of c.90 new houses during 2014-17. |

Additional Information

Higher and Lower Mills were leased in 1832 to Martin Swindells and Thomas Oliver in partnership. At some point, presumably early in the Swindells-Oliver occupation, the second Higher Mill was built. This was essentially an old-style cotton mill. The rooms were taller than in the old mill, with taller windows. The new mill was wider, but still narrow enough for a single-span queen-post roof. The Swindells-Oliver partnership was dissolved in 1842.[2]

References

Clicking the reference description takes you back to the text

- History of the Firm during 150 Years, Revd. A C. Oliver, 1940

- Kerridge Ridge & Ingersley Vale, An Historical Study, George Longden, 2002

- Bryon Holmes, site plumbing engineer, 1950s

Your Historic Documents

Please don't chuck out those historic documents and pictures! Find out why here.

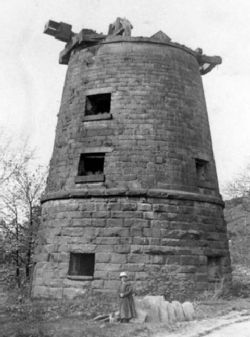

Kerridge Windmill

To the left of the cottages at Five Ashes, along Windmill Lane, there now stands a nice garden with a new stone wall around it. The lawn marks the spot where Kerridge windmill once stood (left). It is thought that the mill was actually second hand and came from Macclesfield Common (see panel below), part of Charles Roe’s industrial complex, developed from 1758. A description of the copper works written in the 1790s mentions ‘a large windmill for grinding the ore.‘ The copper works closed in 1801, but that windmill was converted to corn milling, and was in full use by 18061.